Product Description

1

Products

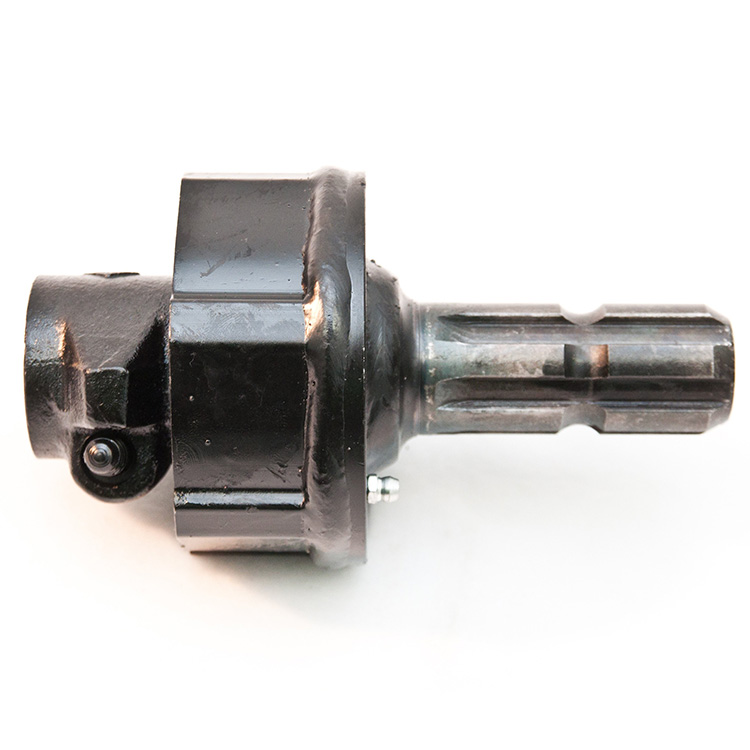

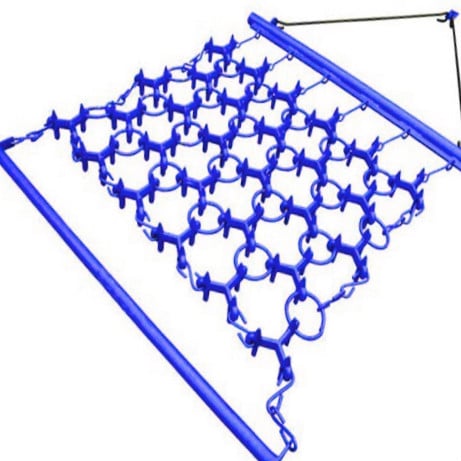

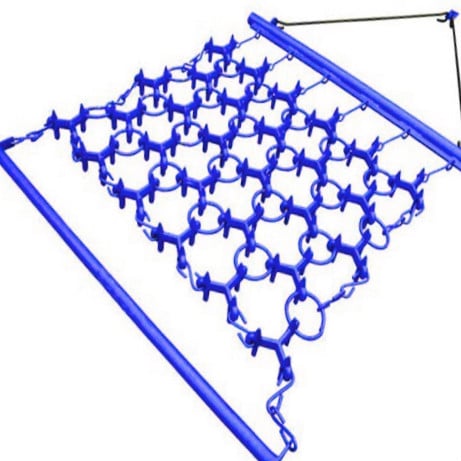

Name: Made in China OEM customized die forging steel agricultural machinery parts drive axle yoke shaft

Material: 40CrMo

Weight: From .2kg-5kg

Packing: wooden case

Min order: 1000pcs

Customized production is available as your drawings or sample.

| Process | Die Forging | |

| Material | Stainless Steel, Carbon Steel, Alloy Steel | |

| Weight | 0.1Kg~20Kg | |

| Heat Treatment | Quenching, Annealing,Tempering,Normalizing, Quenching and Tempering | |

| Testing instrument | composition testing | Spectrometer, Metallographic microscope |

| Performance testing | Hardness tester, Tensile testing machine | |

| Size Measuring | CMM,Micrometer, Vernier Caliper, Depth Caliper, feeler gauge | |

| Thread Gauge , Height Gauge | ||

| Roughness | Ra1.6~Ra6.3 | |

| Machining Equipment | CNC Center , CNC Machines, Turning, Drilling, Milling, boring machine,Grinding Machines, | |

| Wire EDM,Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | ||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | |

| Surface Treatment | Shot Blast , Powder Coating, Polishing, Galvanized , Chrome Plated | |

| Production Capacity | 60000T / Years | |

| Lead Time | Normally 30 – 45 Days. | |

| Payment Terms | T/T , L/C | |

| Material Standard | ASTM , AISI , DIN , BS, JIS, GB, | |

| Certification | ISO9001:2008, IATF16949:2016 | |

2

Products Quality Control

Quality control involve the inspection and control of incoming materials, production processes, and finished products.

The quality control process includes,

1 First of all, the incoming raw materials with random sampling are analyzed by metallographic microscope to ensure that the chemical composition meets the production requirements

2 Then In the production process, there are QC staffs timely sampling ensure that the products are free of defects in the manufacturing process, and to coordinate and handle any abnormal quality issues may be occurred.

3 The final step of production process is magnetic particle flaw detector of the metal parts to detect it’s hidden crack or other defects.

4 All the finished metal parts is sampled in proportion and sent to the laboratory for various mechanical performance tests and size measurement, and the surface quality is manually 100% inspected.

The relevant testing equipment pictures are as following:

3

Quality Management System Control:

We strictly carry out system management accordance with iso9001 and ts16949 quality standards. And 5S lean production management is implemented on the production site.

The production management site as following:

4

Our Advantages:

Brand

Our parent company, HiHangZhou Group, is a world-renowned high-end machinery manufacturing enterprise with 40 domestic subsidiaries and branches and 8 foreign manufacturing plants. Has long-term experience and good reputation in cooperation with world-renowned enterprises.

Technology

We have a complete production process and equipment research and development capabilities for ferrous metals forming. More than 25 years of production experience in forging equipment and casting equipment manufacturers, make us more thoroughly get all the performance of each equipment. One-third of our company’s employees are technician and R&D personnel, ensuring that high-quality products are produced with high efficiency.

Service

We can provide custom and standard manufacturing services with multiple manufacturing process integrations. The quality and delivery of products can be fully guaranteed, and the ability to communicate quickly and effectively.

Culture

The unique corporate culture can give full play to the potential of individuals and provide a strong vitality for the sustainable development of the company.

Social responsibility

Our company strictly implements low-carbon environmental protection, energy-saving and emission-reduction production, and is a benchmark enterprise in local region.

5

Company Culture

Our Vision

To become 1 of the leading companies

Our Mission

To become a platform for employees to realize their dream

To become 1 of the transforming and upgrading pacemaker of Chinese enterprises

To set the national brands with pride

Our Belief

Strive to build the company into an ideal platform for entrepreneurs to realize their self-worth and contribute to the society

Values

Improvement is innovation, everyone can innovate

innovation inspired and failures tolerated

6

FAQ

1.

Q: Are you a trading company or a manufacturer?

A: Obviously we are a manufacturer of forging products, casting products and also have a high level of machining capabilities.

2.

Q: What series products do your have?

A: We are mainly engaged in forming processing of ferrous metals, including processing by casting , forging and machining. As you know, such machinery parts can be observed in various industries of equipment manufacturing.

3

Q: Do you provide samples? is it free?

A: Yes, we commonly provide samples according to the traditional practice, but we also need customers to provide a freight pay-by-account number to show mutual CZPT of cooperation.

4

Q: Is OEM available?

A: Yes, OEM is available.

5

Q: What’s your quality guarantee?

A: We insist that the survival of the company should depend on the products quality continuous improvement, without which we cannot survive for long. We carry out strictly product quality control for every process from incoming materials, production process to finished products via advanced detection instrument and equipment. We also invite independent third parties to certify our quality and management systems. Till now we have passed ISO/TS16949 and SGS certification .

6

Q. How about the Packing?

A: We usually use the iron box, or wooden case, also it can be customized according to customer’s demands.

7

Q: What is your minimum order quantity?

A: Yes, we require all international orders to have an minimum order quantity. The quantity is up to the exact products feature or property such as the material, weight, construction etc.

8

Q: What is the lead time?

A: Generally our forging products and casting products need to make new dies or molds, the time of making new dies or molds and samples within 30-45 days, and the large batch production time within 30-45 days. it’s also according to the parts structural complexity and quantity.

9

Q: What kinds of payment methods do you accept?

A: You can make the payment by T/T or L/C. 30% deposit in advance, 70% balance against the copy of B/L.

Certification

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Application: | Agricultural Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Tempering |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What factors should be considered when selecting the right drive shaft for an application?

When selecting the right drive shaft for an application, several factors need to be considered. The choice of drive shaft plays a crucial role in ensuring efficient and reliable power transmission. Here are the key factors to consider:

1. Power and Torque Requirements:

The power and torque requirements of the application are essential considerations. It is crucial to determine the maximum torque that the drive shaft will need to transmit without failure or excessive deflection. This includes evaluating the power output of the engine or power source, as well as the torque demands of the driven components. Selecting a drive shaft with the appropriate diameter, material strength, and design is essential to ensure it can handle the expected torque levels without compromising performance or safety.

2. Operating Speed:

The operating speed of the drive shaft is another critical factor. The rotational speed affects the dynamic behavior of the drive shaft, including the potential for vibration, resonance, and critical speed limitations. It is important to choose a drive shaft that can operate within the desired speed range without encountering excessive vibrations or compromising the structural integrity. Factors such as the material properties, balance, and critical speed analysis should be considered to ensure the drive shaft can handle the required operating speed effectively.

3. Length and Alignment:

The length and alignment requirements of the application must be considered when selecting a drive shaft. The distance between the engine or power source and the driven components determines the required length of the drive shaft. In situations where there are significant variations in length or operating angles, telescopic drive shafts or multiple drive shafts with appropriate couplings or universal joints may be necessary. Proper alignment of the drive shaft is crucial to minimize vibrations, reduce wear and tear, and ensure efficient power transmission.

4. Space Limitations:

The available space within the application is an important factor to consider. The drive shaft must fit within the allocated space without interfering with other components or structures. It is essential to consider the overall dimensions of the drive shaft, including length, diameter, and any additional components such as joints or couplings. In some cases, custom or compact drive shaft designs may be required to accommodate space limitations while maintaining adequate power transmission capabilities.

5. Environmental Conditions:

The environmental conditions in which the drive shaft will operate should be evaluated. Factors such as temperature, humidity, corrosive agents, and exposure to contaminants can impact the performance and lifespan of the drive shaft. It is important to select materials and coatings that can withstand the specific environmental conditions to prevent corrosion, degradation, or premature failure of the drive shaft. Special considerations may be necessary for applications exposed to extreme temperatures, water, chemicals, or abrasive substances.

6. Application Type and Industry:

The specific application type and industry requirements play a significant role in drive shaft selection. Different industries, such as automotive, aerospace, industrial machinery, agriculture, or marine, have unique demands that need to be addressed. Understanding the specific needs and operating conditions of the application is crucial in determining the appropriate drive shaft design, materials, and performance characteristics. Compliance with industry standards and regulations may also be a consideration in certain applications.

7. Maintenance and Serviceability:

The ease of maintenance and serviceability should be taken into account. Some drive shaft designs may require periodic inspection, lubrication, or replacement of components. Considering the accessibility of the drive shaft and associated maintenance requirements can help minimize downtime and ensure long-term reliability. Easy disassembly and reassembly of the drive shaft can also be beneficial for repair or component replacement.

By carefully considering these factors, one can select the right drive shaft for an application that meets the power transmission needs, operating conditions, and durability requirements, ultimately ensuring optimal performance and reliability.

Can you provide real-world examples of vehicles and machinery that use drive shafts?

Drive shafts are widely used in various vehicles and machinery to transmit power from the engine or power source to the wheels or driven components. Here are some real-world examples of vehicles and machinery that utilize drive shafts:

1. Automobiles:

Drive shafts are commonly found in automobiles, especially those with rear-wheel drive or four-wheel drive systems. In these vehicles, the drive shaft transfers power from the transmission or transfer case to the rear differential or front differential, respectively. This allows the engine’s power to be distributed to the wheels, propelling the vehicle forward.

2. Trucks and Commercial Vehicles:

Drive shafts are essential components in trucks and commercial vehicles. They are used to transfer power from the transmission or transfer case to the rear axle or multiple axles in the case of heavy-duty trucks. Drive shafts in commercial vehicles are designed to handle higher torque loads and are often larger and more robust than those used in passenger cars.

3. Construction and Earthmoving Equipment:

Various types of construction and earthmoving equipment, such as excavators, loaders, bulldozers, and graders, rely on drive shafts for power transmission. These machines typically have complex drivetrain systems that use drive shafts to transfer power from the engine to the wheels or tracks, enabling them to perform heavy-duty tasks on construction sites or in mining operations.

4. Agricultural Machinery:

Agricultural machinery, including tractors, combines, and harvesters, utilize drive shafts to transmit power from the engine to the wheels or driven components. Drive shafts in agricultural machinery are often subjected to demanding conditions and may have additional features such as telescopic sections to accommodate variable distances between components.

5. Industrial Machinery:

Industrial machinery, such as manufacturing equipment, generators, pumps, and compressors, often incorporate drive shafts in their power transmission systems. These drive shafts transfer power from electric motors, engines, or other power sources to various driven components, enabling the machinery to perform specific tasks in industrial settings.

6. Marine Vessels:

In marine applications, drive shafts are commonly used to transmit power from the engine to the propeller in boats, ships, and other watercraft. Marine drive shafts are typically longer and designed to withstand the unique challenges posed by water environments, including corrosion resistance and appropriate sealing mechanisms.

7. Recreational Vehicles (RVs) and Motorhomes:

RVs and motorhomes often employ drive shafts as part of their drivetrain systems. These drive shafts transfer power from the transmission to the rear axle, allowing the vehicle to move and providing propulsion. Drive shafts in RVs may have additional features such as dampers or vibration-reducing components to enhance comfort during travel.

8. Off-Road and Racing Vehicles:

Off-road vehicles, such as SUVs, trucks, and all-terrain vehicles (ATVs), as well as racing vehicles, frequently utilize drive shafts. These drive shafts are designed to withstand the rigors of off-road conditions or high-performance racing, transmitting power efficiently to the wheels and ensuring optimal traction and performance.

9. Railway Rolling Stock:

In railway systems, drive shafts are employed in locomotives and some types of rolling stock. They transfer power from the locomotive’s engine to the wheels or propulsion system, enabling the train to move along the tracks. Railway drive shafts are typically much longer and may have additional features to accommodate the articulated or flexible nature of some train configurations.

10. Wind Turbines:

Large-scale wind turbines used for generating electricity incorporate drive shafts in their power transmission systems. The drive shafts transfer rotational energy from the turbine’s blades to the generator, where it is converted into electrical power. Drive shafts in wind turbines are designed to handle the significant torque and rotational forces generated by the wind.

These examples demonstrate the broad range of vehicles and machinery that rely on drive shafts for efficient power transmission and propulsion. Drive shafts are essential components in various industries, enabling the transfer of power from the source to the driven components, ultimately facilitating movement, operation, or the performance of specific tasks.

Are there variations in drive shaft designs for different types of machinery?

Yes, there are variations in drive shaft designs to cater to the specific requirements of different types of machinery. The design of a drive shaft is influenced by factors such as the application, power transmission needs, space limitations, operating conditions, and the type of driven components. Here’s an explanation of how drive shaft designs can vary for different types of machinery:

1. Automotive Applications:

In the automotive industry, drive shaft designs can vary depending on the vehicle’s configuration. Rear-wheel-drive vehicles typically use a single-piece or two-piece drive shaft, which connects the transmission or transfer case to the rear differential. Front-wheel-drive vehicles often use a different design, employing a drive shaft that combines with the constant velocity (CV) joints to transmit power to the front wheels. All-wheel-drive vehicles may have multiple drive shafts to distribute power to all wheels. The length, diameter, material, and joint types can differ based on the vehicle’s layout and torque requirements.

2. Industrial Machinery:

Drive shaft designs for industrial machinery depend on the specific application and power transmission requirements. In manufacturing machinery, such as conveyors, presses, and rotating equipment, drive shafts are designed to transfer power efficiently within the machine. They may incorporate flexible joints or use a splined or keyed connection to accommodate misalignment or allow for easy disassembly. The dimensions, materials, and reinforcement of the drive shaft are selected based on the torque, speed, and operating conditions of the machinery.

3. Agriculture and Farming:

Agricultural machinery, such as tractors, combines, and harvesters, often requires drive shafts that can handle high torque loads and varying operating angles. These drive shafts are designed to transmit power from the engine to attachments and implements, such as mowers, balers, tillers, and harvesters. They may incorporate telescopic sections to accommodate adjustable lengths, flexible joints to compensate for misalignment during operation, and protective shielding to prevent entanglement with crops or debris.

4. Construction and Heavy Equipment:

Construction and heavy equipment, including excavators, loaders, bulldozers, and cranes, require robust drive shaft designs capable of transmitting power in demanding conditions. These drive shafts often have larger diameters and thicker walls to handle high torque loads. They may incorporate universal joints or CV joints to accommodate operating angles and absorb shocks and vibrations. Drive shafts in this category may also have additional reinforcements to withstand the harsh environments and heavy-duty applications associated with construction and excavation.

5. Marine and Maritime Applications:

Drive shaft designs for marine applications are specifically engineered to withstand the corrosive effects of seawater and the high torque loads encountered in marine propulsion systems. Marine drive shafts are typically made from stainless steel or other corrosion-resistant materials. They may incorporate flexible couplings or dampening devices to reduce vibration and mitigate the effects of misalignment. The design of marine drive shafts also considers factors such as shaft length, diameter, and support bearings to ensure reliable power transmission in marine vessels.

6. Mining and Extraction Equipment:

In the mining industry, drive shafts are used in heavy machinery and equipment such as mining trucks, excavators, and drilling rigs. These drive shafts need to withstand extremely high torque loads and harsh operating conditions. Drive shaft designs for mining applications often feature larger diameters, thicker walls, and specialized materials such as alloy steel or composite materials. They may incorporate universal joints or CV joints to handle operating angles, and they are designed to be resistant to abrasion and wear.

These examples highlight the variations in drive shaft designs for different types of machinery. The design considerations take into account factors such as power requirements, operating conditions, space constraints, alignment needs, and the specific demands of the machinery or industry. By tailoring the drive shaft design to the unique requirements of each application, optimal power transmission efficiency and reliability can be achieved.

editor by CX 2023-10-23

china wholesaler Heavy Duty Shaft for Agricultural Machinery 09s00A Made in China manufacturers

Solution Description

This is travel shaft/axle , CZPT ized for agricultral machinery , machine instrument , construction machinery…… with substantial precision high energy for heavy responsibility . High good quality solution created by competent capable devices and controlled below IATF16949 or ISO9001 techniques. We are professional and practiced in CZPT and source transmission areas(rotary parts in drive technique) this kind of as shafts/axles/spindles , bearings , gears for CZPT machinery .

| Portion NO | 20110HDG05001 |

| Materials | Alloy Steel |

| Precision | IT4-IT9 |

| Heat Treatment | Quenching , Carburization ,Nitriding |

AND CZPT ry Organization is skilled and practiced at mechanical transmission elements , specialize in CZPT and supply bearings, shafts and gears for transmission method (rotary elements) . These elements are assembled with each other and operate together as crucial basic areas in a device or instrument . The appropriate style and higher precision,trustworthy parts will make the equipment has a best perform and the efficient existence.

Initial of all, to pick the bearing and properly design and style it is an essential action. In get to meet up with the excellent state of products , we need to have to know the envisioned features and precision stage, effective life of the machinery, and also require to know the condition which the transmission method performs , such as the speed/load/temperature selection, hence decide the kind of bearing , cage , precision class , lubrication , inner clearance and so on . We are specialist to style bearing and deal with producing , support you to develop a new tools , or to boost the current items , or sourcing and supply you much more value-efficient items .

2nd, CZPT practiced team staff are with appreciable experience in style and manufacture of the shaft, by means of optimized manufacturing process and processing equipments , strictly handle top quality in approach , commonly source to CZPT CZPT ers all above the world . Our Shafts not only fulfill the efficiency of the put in equipment, but also with the most cost-powerful.

Finally, we are ready to generate gears , module .5-12 , OD2000mm max. . Our gear manufacturing line supports us to broaden cooperating with CZPT equipment such as design machinery , agriculture equipment , crane , household equipment , backyard garden machinery…specially , we have several many years of expertise in generation of hydraulic pump equipment , floor tooth precision course 7 of ISO/GB(equal to AGMA11) .

We are capable to assistance CZPT CZPT ers to build and enhance the goods , we are professional and experienced to propose and examine with CZPT ers about designing bearings and shafts , manufacturing technology , quality ….our team will manage top quality strictly and enhance consistently while the purchase put , so as to give CZPT ers with the proper , reliable and competitive goods – this is CZPT benefit. Qur staff aid to make your getting relaxation certain, from design and style , produce to production for optimization.

Our items have been commonly employed in a wide variety of machinery and cars, such as E-bus, E-Bike, ATV, CZPT Tool, Reducer, CZPT ctric CZPT , printing equipment, meals machinery, backyard garden equipment, building equipment, CZPT appliances…

China manufacturer & factory supplier for factory in Cotonou Benin manufacturer for crown Pinion Angular Bevel Gear Automobile Engineering Truck for Agricultural Machinery With high quality best price & service

ISO 9001 qualified company of precision roller chains. Sorts consist of one and a number of strand, hollow pin, aspect bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains.Because of to our sincerity in supplying best provider to our clientele, comprehending of your wants and overriding sense of duty towards filling purchasing demands,a specialized supplier of a full assortment of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Fast Particulars

- Relevant Industries:

-

Manufacturing Plant

- Nearby Near up of two yokes with the common joint. Be aware the slight oozing of grease from the UJ seal ends, the clump of grease is from within the yoke splined shaft location –Travel (outer) yoke has a feminine (normal spline) gap and “Y” shape conclude that is the universal joint (UJ) mount. –UJ is a cross shaped casting obtaining roller bearings enclosed with caps at all four details and is held into the yoke with four “C” clips –Internal yoke and push shaft is one more yoke welded to the drive finish, of the generate shaft. –Pushed shaft and inner yoke is the driven shaft that rides inside of the push shaft and has a yoke welded at the driven conclude –UJ yet another UJ as aboveService Spot:

-

None

Our organization is found in XiHu HangZhou Zhejiang Province. T

- Application:

-

Mechanical Equipment

- Surface treatment:

-

Polishing

- Processing:

-

Turning

- Tolerance:

-

Customer’s Drawing Ask for

- Heat therapy:

-

Higher Frequency Induction Hardening

- Certificate:

-

ISO9001:2009/TS 16949

- Service:

-

24 Hours On-line

These are compact, weighty-obligation drives that provide lengthy-existence functionality functions and simplified upkeep. They include double and triple reduction units. They are obtainable in a assortment of configurations for optimum positioning adaptability. They provide very good energy and longevity. The large energy output shaft assures ability for substantial torque and overhung hundreds.

Provide Capacity

- Offer Capacity:

- 5000 Piece/Pieces per Thirty day period

Packaging & Shipping

- Packaging Specifics

- Neutral paper packaging,picket containers for outer box or in accordance to buyer desire

- Port

- shanghai Port/Ningbo Port

-

Guide Time

: -

Amount(Pieces) one – a thousand >1000 Est. Time(times) fifteen To be negotiated

On the internet Customization

We At any time-Electrical power Group with 4 branches in excess of 1200 personnel is a single of the largest transmission components and machining products producers in China

Merchandise Description:

We specialized in manufacturing car gears , motorbike gears, gearbox, unique vehicle (energy takeoff, snowmobiles, engineering autos) gears, generator equipment, stainless metal ice crusher and so forth.

|

Content |

1020,1045,20CrMnTi, and so forth. |

|

Machining Procedure |

Equipment Hobbing , Equipment Shaping, Gear Shaving, Gear Grinding |

|

Modules |

one., 1.twenty five, 1.5, 1.75, 2., 2.25, 2.5….8. etc. |

|

Warmth Treatment method |

Carburizing & Quenching, Carbonitriding |

|

Normal |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

China manufacturer & factory supplier for Agricultural in Tbilisi Georgia Machinery Pto Shaft Cross Kit,High Quality Universal Joint With high quality best price & service

guidance essential.Our item assortment includes all sorts of helical gear, spur gear, bevel gear, equipment rack, worm gear, sprockets,chains, bearings, pto shaft, agricultural gearboxes.

Overview

Quick Information

- Warranty:

-

1.5 years

- Applicable Industries:

-

Production Plant

- Right after Guarantee Provider:

-

On the internet help

- Regional Service Location:

-

None

- Showroom Spot:

-

Italy

- Sort:

-

Bearing

- Spot of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Local Support Place:

-

Italy

- certificate:

-

CE

- Substance:

-

Metallic

- Processing of yoke:

-

Forging

- Style:

-

Tailored

- Certification:

-

CE Certificate

PTO Adapters To avoid likely connectivity problems, you might want to consider a PTO Adapter for your tractor. The PTO adapter extends the relationship to the employ, offering additional space for the PTO shaft to change without having touching the Arm Weldment or other areas of your tractor or the implement.

Offer Capacity

- Source Capacity:

- 40000 Piece/Parts for every Month

Packaging & Supply

-

The firm was certified by ISO9001:2008 Good quality Administration System.

- Packaging Particulars

- wooden crate

- Port

- Ningbo

Online Customization

Merchandise Data

Merchandise Data

PTO Shaft

The power just take-off (PTO) is a advanced mechanism, making it possible for implements to attract power from the engine and transmit it to an additional application. It performs as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power just take-off shaft (PTO shaft) is a crucial ingredient, designed and produced for continuous weighty-obligation use. A great PTO shaft need to be robust ample to bear the torsion and shear pressure and lessen vibration.

Setforge, the forging subsidiary of Ever-Energy Group, manufactures cold extruded PTO shafts for all sorts of agriculture automobiles. Our PTO shafts provide wonderful dependability and durability for the duration of day-to-day use.

EP Group has been internationally identified as a reputable world-wide provider. Our condition-of-the-artwork manufacturing method and knowledgeable engineers make sure the best-top quality of all Farinia parts.

| After Warranty Services | Movie technical assistance |

| Relevant Industries | Manufacturing Plant |

| Neighborhood Services Place | Italy |

| Showroom Spot | Italy |

| Warranty | 1.5 a long time |

| Sort | Bearing |

| Location of Origin | China |

| China | Zhejiang |

| Brand Identify | EPG |

| certification | CE |

| Content | Metal |

| Processing of yoke | Forging |

| Style | Tailored |

| Certification | CE Certificate |

Merchandise Show

Product Display

CAT 23 Swift Hitch

PTO Travel Line Gen …

12″ Diameter Compa …

CompanyInfo

Business Profile

At any time-Power Group

EPG have high-tech machinery and check equipment. We can produce planet class high precision items.

Certifications

Certifications

Shipment & Payment

Our Benefits

A: Your inquiry connected to our goods or charges will be replied in 24 hrs.

B: Security of your product sales region, concepts of style and all your private details.

C: Ideal high quality and competitive price tag.

……

faq

FAQ

1) How can I area order?

A: You can get in touch with us by e mail about your get details, or spot buy on line.

2) How can I pay out you?

A: Soon after you validate our PI, we will ask for you to spend. T/T (HSBC bank) and Paypal, Western Union are the most typical approaches we are using.

……

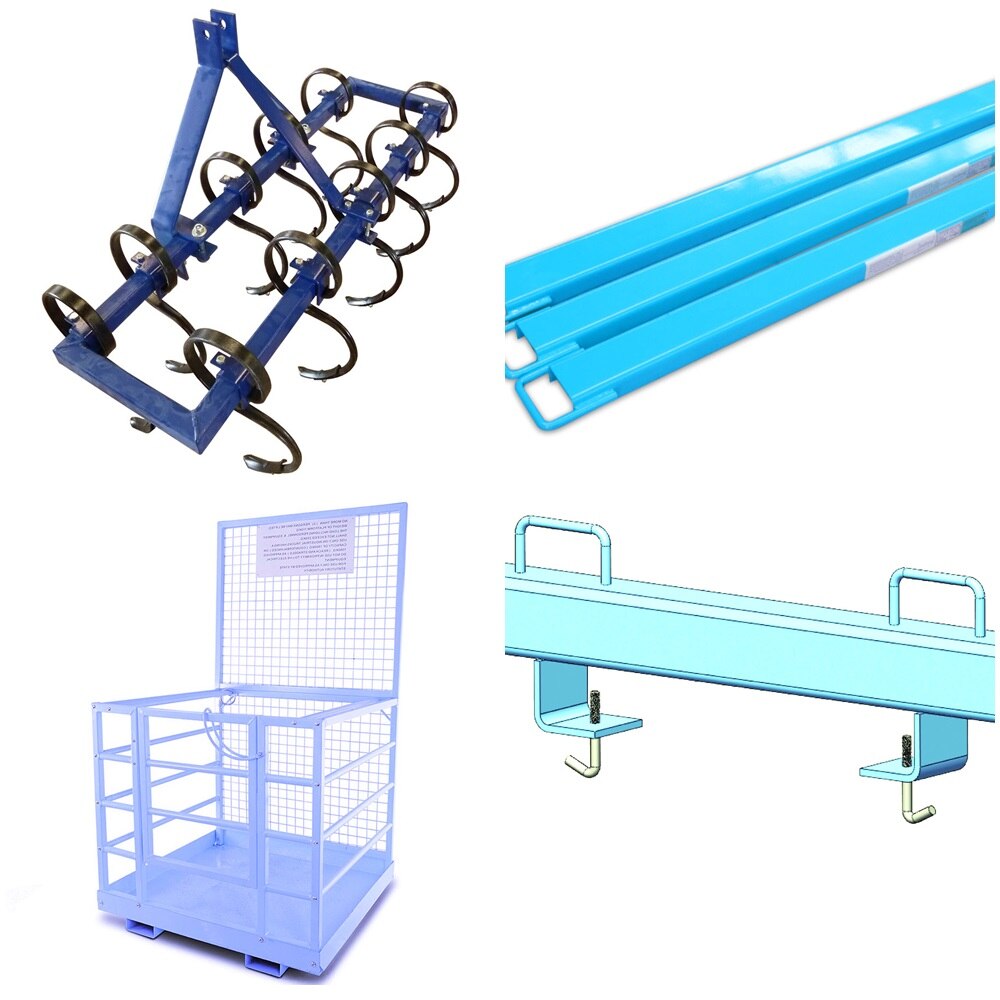

Best China manufacturer & factory china in Kolhapur India manufacturer Hot selling high quality tractor disc plough is suitable for agricultural machinery With high quality best price

It has established stable cooperation with several well recognized universities and institutes in china this sort of as, Zhejiang College, Jilin University, Technological committee of countrywide chain travel common, Institute of countrywide chain travel, Zhejiang application engineering content institute, Huhan material protection institute and it cooperated to identified China Very first Automobile chain institute with National chain generate institute.

Overview

Fast Information

- Guarantee:

-

one.5 a long time

- Relevant Industries:

-

Farms

- After Guarantee Support:

-

Movie specialized assist

- Regional Service Location:

-

Canada, Turkey

- Showroom Location:

-

Egypt

- Video clip outgoing-inspection:

-

Offered

- Machinery Check Report:

-

Presented

- Marketing Type:

-

New Merchandise 2020

- Guarantee of core factors:

-

one.5 a long time

- Core Elements:

-

Gearbox, Equipment

- Key Selling Factors:

-

Long Services Life

- Substance:

-

65Mn or Boron metal

- Colour:

-

Black Yellow Blue

- Title:

-

Tractor Disc Plough for Farm Device

- Search term:

-

20kg

- Hardness:

-

HRC38~forty four

- Diameter:

-

510 or 560mm

- Gap Dimension:

-

Squared 31*31mm or optional

- Thickness:

-

3~12mm

Packaging Near up of two yokes with the common joint. Observe the slight oozing of grease from the UJ seal ends, the clump of grease is from inside the yoke splined shaft location –Drive (outer) yoke has a woman (typical spline) gap and “Y” shape finish that is the common joint (UJ) mount. –UJ is a cross formed casting possessing roller bearings enclosed with caps at all 4 points and is held into the yoke with four “C” clips –Inner yoke and generate shaft is one more yoke welded to the travel finish, of the drive shaft. –Driven shaft and internal yoke is the driven shaft that rides inside of the push shaft and has a yoke welded at the driven finish –UJ yet another UJ as previously mentioned& Shipping and delivery

-

Direct Time

: -

Quantity(Luggage) one – 500 501 – one thousand >1000 Est. Time(days) 38 45 To be negotiated

On-line Customization

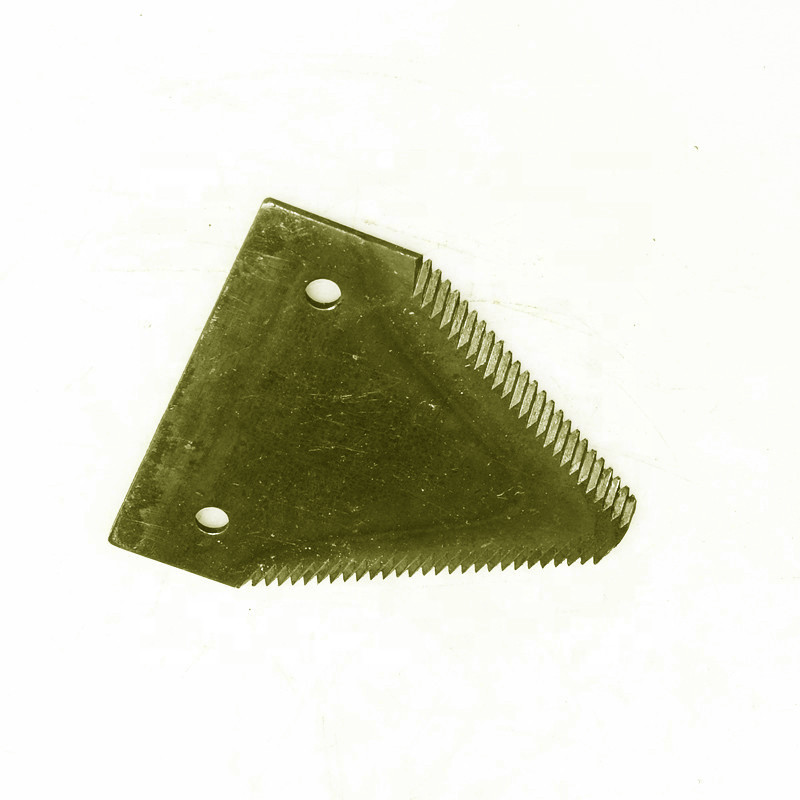

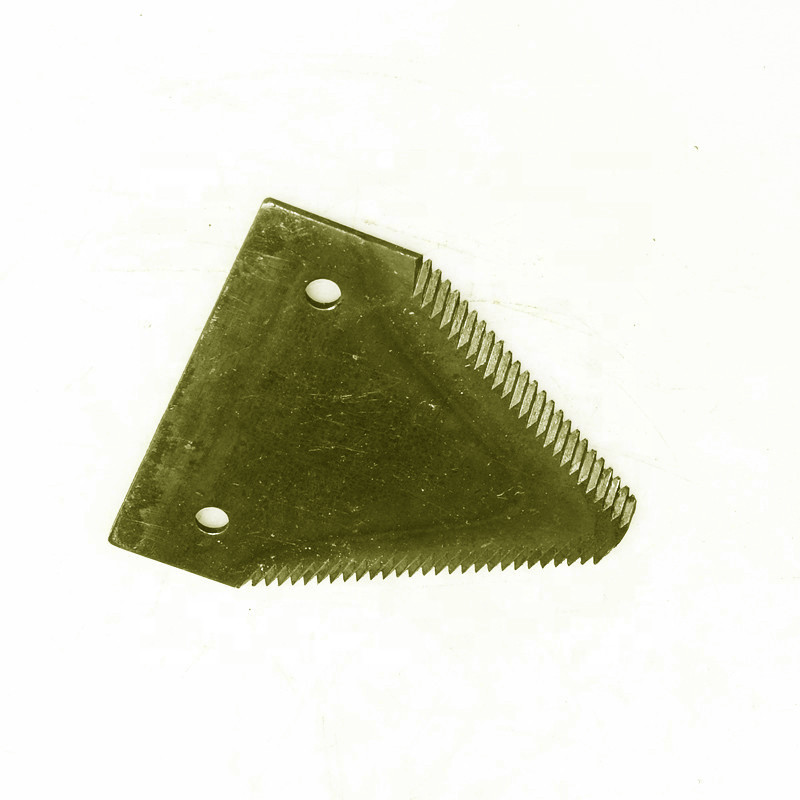

Product Description

|

Solution Identify |

Agricultural equipment parts |

|

Content |

65mn,60si2mn,38MnB5 |

|

Color |

crimson,black,blue or as your need |

|

Normal |

IS9001 |

|

Attribute |

Long making use of life and the affordable cost |

|

Surface Treatment |

Spray Paint,Energy Painting,Galvanized |

|

Advantages |

Professional production staff,excellent engineer,high good quality productions |

|

Utilized |

Farm Device |

Goods Display

Our Business

Manufacturing unit

Our Manufacturing unit

Workshop

Our Workshop

Warehouse

Our Warehouse

Staff

Our Group

Packing & Supply

Packing Information : Wooden cases or Tito

Shipping Details : 45 days soon after order

one. Particular logistics packaging

two. Suitable carton dimension

3. Shock bubble film

four. Skilled placement

five. Professional shock

six. Comprehensive bundle

Our Certifications

Client Image

ABOUT US

OurHIGH-Finish OR Standard – OUR Customers HAVE THE Option Consumers can gain from our strengths in two quite various locations of our portfolio: on the a single hand, we provide a wide selection of products in the reduced-to-mid efficiency variety. On the other, we build an array of answers for even the most tough generate apps. manufacturing unit is specializing in the generation of agricultural machinery and forestry equipment chopping tool items, supplies this sort of as 65MN, 60SI2MN, 30MNB5,45#, and numerous other sorts of resources. Merchandise: harvester blade, tiller blade, blade mower, deep plowing machine components and so on

A skilled rotarycolter manufacturing unit

EPG – a single of the greatest Agri-Machinery parts manufacturing facility in China Co., Ltd., our factory has 19 years of background. The company has 200 workers, including 18 skilled and technical developers and twenty screening staff.It specializes in producing more than 5000 agricultural equipment items and offering them to 85 nations around the world

FAQ

Q: Are you investing organization or producer ?

A: We are manufacturing facility.

Q: How extended is your delivery time?

A: Normally it is 5-ten times if the goods are in inventory. or it is fifteen-twenty times if the items are not in inventory, it is in accordance to quantity.

Our organization has reliable financial strength, builds up a technician group contingent with higher top quality, possesses the manufacturing assembly line of technicalization in China and perfect program examining on solution quality and runs marketing networks during the region. Q: Do you give samples ? is it free of charge or additional ?

A: Of course, we could supply the sample for totally free demand but do not shell out the expense of freight.

Q: What is your conditions of payment ?

A: Payment=1000USD, 30% T/T in progress ,balance before shippment.

If you have an additional question, pls come to feel free to speak to us as underneath:

Contact

Alan

E-mail :hzpt @hzpt.com

WeChat.:hzptusa