Product Description

Tractor Pto Driveshaft Driveline Factory Hollow Spline Cardan Adapter Universal Joint Yoke Flexible Front Prop Rear CV Axle Propeller Automobile Drive Shaft

Product Description

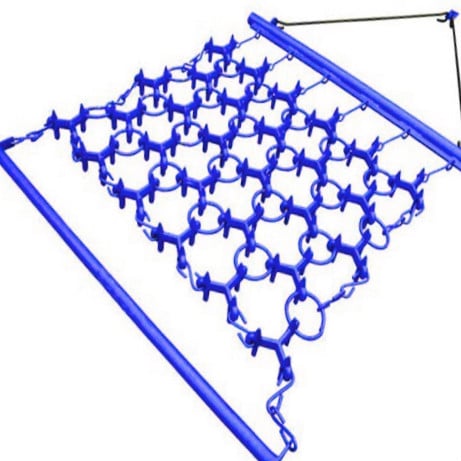

Agricultural truck universal joint steering

PTO Shaft

| Function of PTO Shaft | Drive Shaft Parts & Power Transmission |

| Usage of PTO Shaft | Kinds of Tractors & Farm Implements |

| Yoke Types for PTO Shaft | Double push pin, Bolt pins, Split pins, Pushpin, Quick release, Ball attachment, Collar….. |

| Processing Of Yoke | Forging |

| PTO Shaft Plastic Cover | YW; BW; YS; BS; Etc |

| Colors of PTO Shaft | Green; Orange; Yellow; Black Ect. |

| PTO Shaft Series | T1-T10; L1-L6;S6-S10;10HP-150HP with SA,RA,SB,SFF,WA,CV Etc |

| Tube Types for PTO Shaft | Lemon, Triangular, Star, Square, Hexangular, Spline, Special Ect |

| Processing Of Tube | Cold drawn |

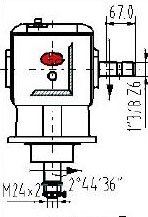

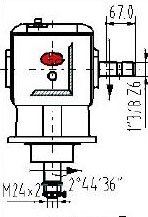

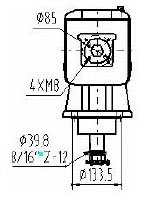

| Spline Types for PTO Shaft | 1 1/8″ Z6;1 3/8″ Z6; 1 3/8″ Z21 ;1 3/4″ Z20; 1 3/4″ Z6; 8-38*32*6 8-42*36*7; 8-48*42*8; |

We also sell accessories for the pto shaft, including :

Yoke: CV socket yoke, CV weld yoke, flange yoke, end yoke, weld yoke, slip yoke

CV center housing, tube, spline, CV socket flange, u-joint, dust cap

Light vehicle drive line

Our products can be used for transmission shafts of the following brands

Toyota, Mitsubishi, Nissan, Isu zu, Suzuki, Dafa, Honda, Hyundai, Mazda, Fiat, Re nault, Kia, Dacia, Ford. Dodge, Land Rover, Peu geot, Volkswagen Audi, BMW Benz Volvo, Russian models

Gear shaft

Company Profile

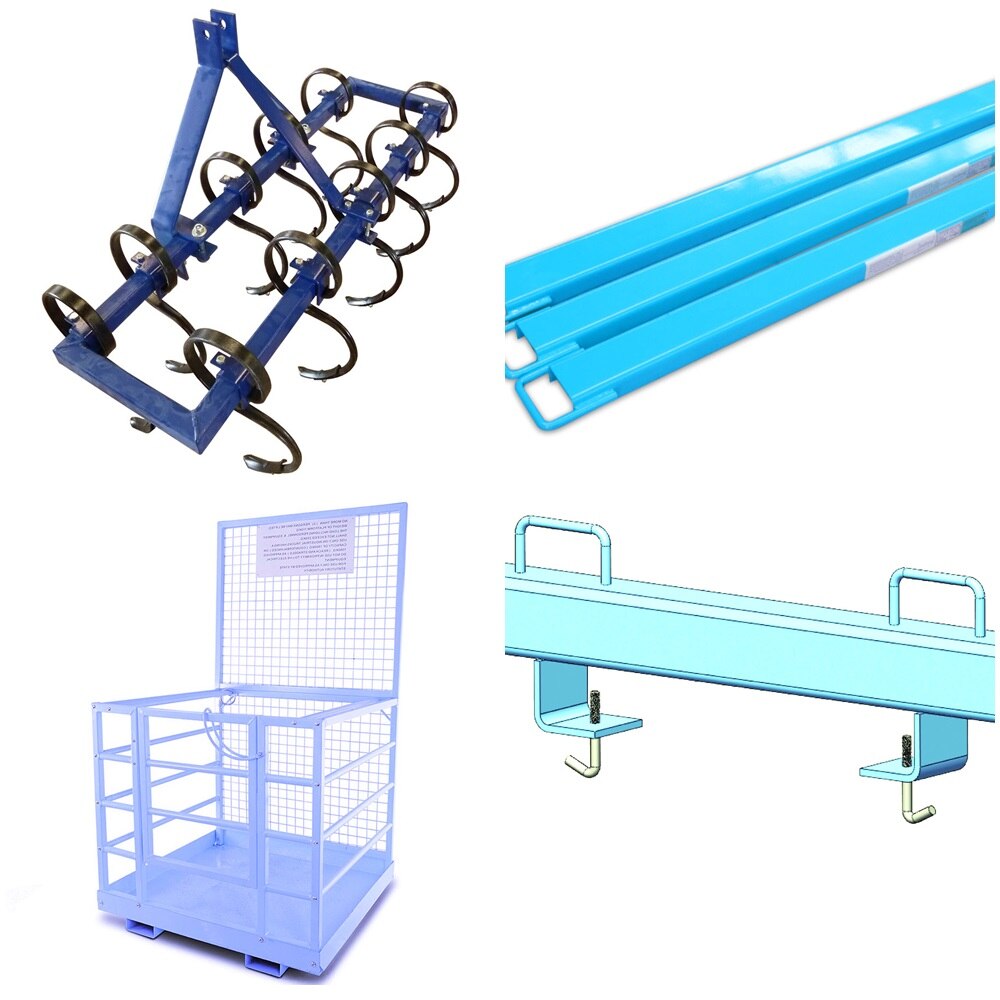

Related Products

Application:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 38/Piece

1 Piece(Min.Order) | |

|---|

Can Rear Drive Shafts Be Adapted for Use in Various Automotive and Industrial Settings?

Rear drive shafts are versatile components that can be adapted for use in various automotive and industrial settings. While their primary function is to transfer power from the engine or transmission to the rear wheels of a vehicle, their design and characteristics allow for customization and integration into different applications. Here’s a detailed explanation of how rear drive shafts can be adapted for use in different settings:

1. Automotive Applications:

Rear drive shafts are commonly used in a wide range of automotive applications, including passenger cars, SUVs, trucks, and commercial vehicles. They are designed to accommodate different drivetrain configurations, such as rear-wheel drive (RWD), four-wheel drive (4WD), and all-wheel drive (AWD). Rear drive shafts can be adapted to specific vehicle models by considering factors such as length, diameter, material selection, and joint type (u-joints or CV joints). Additionally, rear drive shafts can be modified for high-performance vehicles or off-road applications, where they may require enhanced strength, improved balance, or increased articulation capability.

2. Industrial Machinery:

Aside from automotive applications, rear drive shafts can be adapted for use in various industrial machinery. These applications often involve the transfer of power from the engine or motor to driven components, such as pumps, generators, compressors, or industrial equipment. Rear drive shafts used in industrial settings may have different design considerations compared to automotive applications. They may need to withstand higher torque loads, operate under harsh environmental conditions, or have specific dimensional requirements to fit within the machinery’s space constraints. Customization of rear drive shafts allows for seamless integration into diverse industrial applications.

3. Agricultural Equipment:

Rear drive shafts find utility in agricultural equipment as well. Tractors, combines, and other agricultural machinery often require the transfer of power to various implements, such as plows, seeders, or harvesters. Rear drive shafts can be adapted for use in these applications by considering the specific power requirements, torque limitations, and environmental conditions encountered in agricultural settings. They may need to be designed for durability, resistance to debris and moisture, and ease of maintenance. Agricultural rear drive shafts can vary in size, configuration, and material depending on the specific machinery and its intended use.

4. Construction and Off-Road Equipment:

In construction and off-road equipment, rear drive shafts are utilized to transfer power to drivetrain components, such as axles or wheels. These applications often involve challenging operating conditions, including uneven terrain, heavy loads, and extreme temperatures. Rear drive shafts adapted for construction and off-road equipment may require additional reinforcement, specialized joints, or protective coatings to withstand the demanding environments. They may also feature enhanced articulation capability to accommodate the suspension movements and maintain power transfer during off-road or rough terrain operation.

5. Specialized Vehicles and Custom Applications:

Rear drive shafts can be customized and adapted for specialized vehicles and unique applications. Examples include racing cars, military vehicles, armored vehicles, and custom-built off-road vehicles. These applications often demand specific performance characteristics, such as lightweight materials for improved acceleration, high-strength alloys for durability, or advanced joint designs for enhanced articulation. Rear drive shafts can be engineered to meet the unique requirements of these specialized vehicles and custom applications, ensuring efficient power transfer while withstanding the challenges posed by their intended use.

6. Retrofitting and Upgrades:

Rear drive shafts can also be adapted through retrofitting or upgrades to improve the performance or functionality of existing vehicles or machinery. Upgrading to stronger materials, replacing worn-out joints, or modifying the drive shaft’s length or diameter can enhance power transfer efficiency, reduce vibration, or accommodate changes in the vehicle’s configuration. Retrofitting rear drive shafts allows for customization and optimization without the need for complete system redesign, making it a cost-effective way to adapt existing equipment to new requirements or to address specific performance issues.

In summary, rear drive shafts can be adapted for use in various automotive and industrial settings by considering factors such as drivetrain configuration, power requirements, environmental conditions, and specific application needs. Whether it’s for automotive, industrial machinery, agricultural equipment, construction and off-road vehicles, specialized vehicles, or retrofitting purposes, rear drive shafts offer versatility and customization options to ensure efficient power transfer and reliable operation in diverse settings.

Are There Any Emerging Trends in Rear Drive Shaft Technology, Such as Lightweight Materials?

Rear drive shaft technology has been evolving over the years, and there are indeed emerging trends, including the use of lightweight materials, that are shaping the development of rear drive shafts. These trends aim to improve overall vehicle efficiency, performance, and reliability. Here are some notable emerging trends in rear drive shaft technology:

1. Lightweight Materials:

One significant trend in rear drive shaft technology is the utilization of lightweight materials. Traditional rear drive shafts have been predominantly made of steel due to its strength and durability. However, advancements in materials engineering have introduced lightweight alternatives such as aluminum, carbon fiber, and composite materials. These lightweight materials offer comparable or even superior strength while significantly reducing the weight of the drive shaft. By reducing weight, the overall vehicle weight is decreased, leading to improved fuel efficiency, handling, and performance.

2. Composite Drive Shafts:

Composite materials, such as carbon fiber-reinforced polymers (CFRP), are gaining popularity in rear drive shaft construction. Composite drive shafts offer high strength-to-weight ratios, excellent torsional rigidity, and improved damping characteristics compared to traditional steel drive shafts. The use of composites allows for weight reduction while maintaining the necessary structural integrity and performance requirements. Composite drive shafts also exhibit better resistance to corrosion and fatigue, increasing their durability and lifespan.

3. Advanced Manufacturing Techniques:

Advancements in manufacturing techniques have also impacted rear drive shaft technology. Techniques such as automated filament winding and resin transfer molding enable the production of complex shapes and optimized designs for drive shafts. These advanced manufacturing processes allow for precise control over the fiber orientation and resin distribution in composite drive shafts, resulting in enhanced strength, stiffness, and overall performance.

4. Integration of Sensors:

Another emerging trend is the integration of sensors within rear drive shafts. By incorporating sensors, such as strain gauges or torque sensors, into the drive shafts, manufacturers can monitor various parameters, including torque transmission, vibrations, and temperature. This data can be utilized for real-time monitoring, predictive maintenance, and optimizing vehicle performance. Sensor integration enables early detection of potential issues, improving reliability and reducing the risk of drive shaft failures.

5. Adaptive Drive Shaft Systems:

Some manufacturers are developing adaptive drive shaft systems that can actively adjust torsional stiffness based on driving conditions. These systems utilize technologies like electromagnetic clutches or hydraulic mechanisms to vary the stiffness of the drive shaft. By adapting to different driving situations, such as cornering, acceleration, or off-road conditions, adaptive drive shaft systems can optimize power delivery, improve traction, and enhance vehicle stability.

6. Electric Drive Shafts:

With the rise of electric vehicles (EVs) and hybrid vehicles, electric drive shafts are becoming a notable trend. In these vehicles, electric motors are often integrated into the drivetrain, eliminating the need for a traditional mechanical drive shaft. Instead, electric drive shafts transmit torque from the electric motor to the wheels using electrical power. Electric drive shafts offer efficient power transmission, precise control, and the potential for regenerative braking, contributing to the overall performance and energy efficiency of electric and hybrid vehicles.

7. Noise and Vibration Reduction:

Manufacturers are also focusing on reducing noise and vibration levels associated with rear drive shafts. Advanced design techniques, improved material damping properties, and precision manufacturing contribute to minimizing unwanted vibrations and noise transmission to the vehicle’s cabin. By reducing noise and vibration, occupants experience improved comfort and a quieter driving experience.

In summary, emerging trends in rear drive shaft technology include the use of lightweight materials, such as aluminum and composites, advanced manufacturing techniques, sensor integration, adaptive drive shaft systems, electric drive shafts, and efforts to reduce noise and vibrations. These trends aim to enhance vehicle efficiency, performance, durability, and overall driving experience.

How Do Rear Drive Shafts Impact the Performance and Drivability of Vehicles?

Rear drive shafts have a significant impact on the performance and drivability of vehicles. As a crucial component of the drivetrain system, the rear drive shaft affects various aspects of a vehicle’s operation, including power delivery, handling, stability, and overall driving experience. Here’s a detailed explanation of how rear drive shafts impact the performance and drivability of vehicles:

1. Power Transmission:

Rear drive shafts play a vital role in transmitting power from the engine or transmission to the wheels. As the engine generates torque, the rear drive shaft transfers this rotational force to the rear wheels, enabling propulsion and vehicle movement. The efficiency and effectiveness of power transmission through the rear drive shaft directly impact a vehicle’s acceleration, towing capacity, and overall performance.

2. Traction and Stability:

The distribution of power between the rear wheels, controlled by the rear drive shaft and the rear differential, significantly affects a vehicle’s traction and stability. By transmitting torque to the rear differential, the rear drive shaft allows the differential to distribute power to each rear wheel based on traction conditions.

Proper power distribution between the rear wheels ensures balanced traction, reducing the likelihood of wheel slippage or loss of control. This enhances the vehicle’s stability, especially during acceleration, cornering, or driving on uneven or slippery surfaces.

3. Handling and Cornering:

Rear drive shafts influence a vehicle’s handling and cornering capabilities. In rear-wheel drive (RWD) vehicles, the rear drive shaft connects the transmission or transfer case to the rear differential, resulting in a weight distribution biased towards the rear of the vehicle.

This weight distribution, combined with the rear drive shaft’s torque transmission to the rear wheels, contributes to better traction and stability during cornering. RWD vehicles typically exhibit a more balanced and predictable handling characteristic, allowing drivers to maintain better control and confidence while navigating turns.

4. Suspension Compatibility:

Rear drive shafts also need to be compatible with a vehicle’s suspension system. The suspension system allows the wheels to move independently, absorbing bumps, road irregularities, and other disturbances for a smoother ride.

The rear drive shaft must accommodate the vertical movement of the suspension without affecting power transmission. It achieves this by incorporating flexible joints or splines that allow the drive shaft to expand or contract in length as the suspension moves. This compatibility ensures that the rear drive shaft does not hinder the suspension’s ability to absorb shocks and maintain tire contact with the road surface.

5. Drivetrain Efficiency:

The efficiency of a vehicle’s drivetrain system is influenced by the performance of the rear drive shaft. A well-designed and properly maintained rear drive shaft minimizes power losses and mechanical friction, allowing more power to reach the wheels and optimizing overall drivetrain efficiency.

Efficient power transmission through the rear drive shaft contributes to improved fuel efficiency, reduced energy waste, and enhanced performance. Regular maintenance, such as lubrication and alignment, ensures that the rear drive shaft operates smoothly and maximizes its contribution to drivetrain efficiency.

6. Four-Wheel Drive Capability:

In vehicles equipped with four-wheel drive (4WD) or all-wheel drive (AWD) systems, rear drive shafts play a crucial role in enabling four-wheel drive capability. The rear drive shaft transfers torque to the transfer case, which distributes power to both the front and rear differentials.

By facilitating power distribution to all four wheels, rear drive shafts enhance the vehicle’s off-road performance, traction, and stability. Four-wheel drive capability allows the vehicle to tackle challenging terrain, slippery conditions, or uneven surfaces with improved control and maneuverability.

In summary, rear drive shafts have a significant impact on the performance and drivability of vehicles. They affect power transmission, traction, stability, handling, suspension compatibility, drivetrain efficiency, and enable four-wheel drive capability. By understanding and optimizing the design, maintenance, and performance of rear drive shafts, manufacturers and drivers can enhance a vehicle’s overall performance, efficiency, and driving experience.

editor by CX 2024-04-09

China High quality transmission pto drive shaft for agricultural tractor parts drive shaft coupling

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

Guide to Drive Shafts and U-Joints

If you’re concerned about the performance of your car’s driveshaft, you’re not alone. Many car owners are unaware of the warning signs of a failed driveshaft, but knowing what to look for can help you avoid costly repairs. Here is a brief guide on drive shafts, U-joints and maintenance intervals. Listed below are key points to consider before replacing a vehicle driveshaft.

Symptoms of Driveshaft Failure

Identifying a faulty driveshaft is easy if you’ve ever heard a strange noise from under your car. These sounds are caused by worn U-joints and bearings supporting the drive shaft. When they fail, the drive shafts stop rotating properly, creating a clanking or squeaking sound. When this happens, you may hear noise from the side of the steering wheel or floor.

In addition to noise, a faulty driveshaft can cause your car to swerve in tight corners. It can also lead to suspended bindings that limit overall control. Therefore, you should have these symptoms checked by a mechanic as soon as you notice them. If you notice any of the symptoms above, your next step should be to tow your vehicle to a mechanic. To avoid extra trouble, make sure you’ve taken precautions by checking your car’s oil level.

In addition to these symptoms, you should also look for any noise from the drive shaft. The first thing to look for is the squeak. This was caused by severe damage to the U-joint attached to the drive shaft. In addition to noise, you should also look for rust on the bearing cap seals. In extreme cases, your car can even shudder when accelerating.

Vibration while driving can be an early warning sign of a driveshaft failure. Vibration can be due to worn bushings, stuck sliding yokes, or even springs or bent yokes. Excessive torque can be caused by a worn center bearing or a damaged U-joint. The vehicle may make unusual noises in the chassis system.

If you notice these signs, it’s time to take your car to a mechanic. You should check regularly, especially heavy vehicles. If you’re not sure what’s causing the noise, check your car’s transmission, engine, and rear differential. If you suspect that a driveshaft needs to be replaced, a certified mechanic can replace the driveshaft in your car.

Drive shaft type

Driveshafts are used in many different types of vehicles. These include four-wheel drive, front-engine rear-wheel drive, motorcycles and boats. Each type of drive shaft has its own purpose. Below is an overview of the three most common types of drive shafts:

The driveshaft is a circular, elongated shaft that transmits torque from the engine to the wheels. Drive shafts often contain many joints to compensate for changes in length or angle. Some drive shafts also include connecting shafts and internal constant velocity joints. Some also include torsional dampers, spline joints, and even prismatic joints. The most important thing about the driveshaft is that it plays a vital role in transmitting torque from the engine to the wheels.

The drive shaft needs to be both light and strong to move torque. While steel is the most commonly used material for automotive driveshafts, other materials such as aluminum, composites, and carbon fiber are also commonly used. It all depends on the purpose and size of the vehicle. Precision Manufacturing is a good source for OEM products and OEM driveshafts. So when you’re looking for a new driveshaft, keep these factors in mind when buying.

Cardan joints are another common drive shaft. A universal joint, also known as a U-joint, is a flexible coupling that allows one shaft to drive the other at an angle. This type of drive shaft allows power to be transmitted while the angle of the other shaft is constantly changing. While a gimbal is a good option, it’s not a perfect solution for all applications.

CZPT, Inc. has state-of-the-art machinery to service all types of drive shafts, from small cars to race cars. They serve a variety of needs, including racing, industry and agriculture. Whether you need a new drive shaft or a simple adjustment, the staff at CZPT can meet all your needs. You’ll be back on the road soon!

U-joint

If your car yoke or u-joint shows signs of wear, it’s time to replace them. The easiest way to replace them is to follow the steps below. Use a large flathead screwdriver to test. If you feel any movement, the U-joint is faulty. Also, inspect the bearing caps for damage or rust. If you can’t find the u-joint wrench, try checking with a flashlight.

When inspecting U-joints, make sure they are properly lubricated and lubricated. If the joint is dry or poorly lubricated, it can quickly fail and cause your car to squeak while driving. Another sign that a joint is about to fail is a sudden, excessive whine. Check your u-joints every year or so to make sure they are in proper working order.

Whether your u-joint is sealed or lubricated will depend on the make and model of your vehicle. When your vehicle is off-road, you need to install lubricable U-joints for durability and longevity. A new driveshaft or derailleur will cost more than a U-joint. Also, if you don’t have a good understanding of how to replace them, you may need to do some transmission work on your vehicle.

When replacing the U-joint on the drive shaft, be sure to choose an OEM replacement whenever possible. While you can easily repair or replace the original head, if the u-joint is not lubricated, you may need to replace it. A damaged gimbal joint can cause problems with your car’s transmission or other critical components. Replacing your car’s U-joint early can ensure its long-term performance.

Another option is to use two CV joints on the drive shaft. Using multiple CV joints on the drive shaft helps you in situations where alignment is difficult or operating angles do not match. This type of driveshaft joint is more expensive and complex than a U-joint. The disadvantages of using multiple CV joints are additional length, weight, and reduced operating angle. There are many reasons to use a U-joint on a drive shaft.

maintenance interval

Checking U-joints and slip joints is a critical part of routine maintenance. Most vehicles are equipped with lube fittings on the driveshaft slip joint, which should be checked and lubricated at every oil change. CZPT technicians are well-versed in axles and can easily identify a bad U-joint based on the sound of acceleration or shifting. If not repaired properly, the drive shaft can fall off, requiring expensive repairs.

Oil filters and oil changes are other parts of a vehicle’s mechanical system. To prevent rust, the oil in these parts must be replaced. The same goes for transmission. Your vehicle’s driveshaft should be inspected at least every 60,000 miles. The vehicle’s transmission and clutch should also be checked for wear. Other components that should be checked include PCV valves, oil lines and connections, spark plugs, tire bearings, steering gearboxes and brakes.

If your vehicle has a manual transmission, it is best to have it serviced by CZPT’s East Lexington experts. These services should be performed every two to four years or every 24,000 miles. For best results, refer to the owner’s manual for recommended maintenance intervals. CZPT technicians are experienced in axles and differentials. Regular maintenance of your drivetrain will keep it in good working order.

editor by czh 2023-03-03

China Tractor Protective Plastic Sheath Enshrouding Free-Wheel for Agricultural Pto Shaft Drive Shaft High Quality Precious Shafts China Industrial Factory drive shaft parts

Item Description

Tractor Protective Plastic Sheath Enshrouding Totally free-Wheel for Agricultural Pto Shaft Travel Shaft Large High quality Precious Shafts China Industrial Manufacturing unit

|

US $10-999 / Piece | |

100 Pieces (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 8-24 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

###

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) |

|---|

|

US $10-999 / Piece | |

100 Pieces (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 8-24 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

###

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) |

|---|

Driveshaft structure and vibrations associated with it

The structure of the drive shaft is critical to its efficiency and reliability. Drive shafts typically contain claw couplings, rag joints and universal joints. Other drive shafts have prismatic or splined joints. Learn about the different types of drive shafts and how they work. If you want to know the vibrations associated with them, read on. But first, let’s define what a driveshaft is.

transmission shaft

As the demand on our vehicles continues to increase, so does the demand on our drive systems. Higher CO2 emission standards and stricter emission standards increase the stress on the drive system while improving comfort and shortening the turning radius. These and other negative effects can place significant stress and wear on components, which can lead to driveshaft failure and increase vehicle safety risks. Therefore, the drive shaft must be inspected and replaced regularly.

Depending on your model, you may only need to replace one driveshaft. However, the cost to replace both driveshafts ranges from $650 to $1850. Additionally, you may incur labor costs ranging from $140 to $250. The labor price will depend on your car model and its drivetrain type. In general, however, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft market can be divided into four major markets: North America, Europe, Asia Pacific, and Rest of the World. North America is expected to dominate the market, while Europe and Asia Pacific are expected to grow the fastest. Furthermore, the market is expected to grow at the highest rate in the future, driven by economic growth in the Asia Pacific region. Furthermore, most of the vehicles sold globally are produced in these regions.

The most important feature of the driveshaft is to transfer the power of the engine to useful work. Drive shafts are also known as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the engine, transmission, and differential to the front or rear wheels, or both. Due to the complexity of driveshaft assemblies, they are critical to vehicle safety. In addition to transmitting torque from the engine, they must also compensate for deflection, angular changes and length changes.

type

Different types of drive shafts include helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head provide a rotationally secure connection. At least one bearing has a groove extending along its circumferential length that allows the pin to pass through the bearing. There can also be two flanges on each end of the shaft. Depending on the application, the shaft can be installed in the most convenient location to function.

Propeller shafts are usually made of high-quality steel with high specific strength and modulus. However, they can also be made from advanced composite materials such as carbon fiber, Kevlar and fiberglass. Another type of propeller shaft is made of thermoplastic polyamide, which is stiff and has a high strength-to-weight ratio. Both drive shafts and screw shafts are used to drive cars, ships and motorcycles.

Sliding and tubular yokes are common components of drive shafts. By design, their angles must be equal or intersect to provide the correct angle of operation. Unless the working angles are equal, the shaft vibrates twice per revolution, causing torsional vibrations. The best way to avoid this is to make sure the two yokes are properly aligned. Crucially, these components have the same working angle to ensure smooth power flow.

The type of drive shaft varies according to the type of motor. Some are geared, while others are non-geared. In some cases, the drive shaft is fixed and the motor can rotate and steer. Alternatively, a flexible shaft can be used to control the speed and direction of the drive. In some applications where linear power transmission is not possible, flexible shafts are a useful option. For example, flexible shafts can be used in portable devices.

put up

The construction of the drive shaft has many advantages over bare metal. A shaft that is flexible in multiple directions is easier to maintain than a shaft that is rigid in other directions. The shaft body and coupling flange can be made of different materials, and the flange can be made of a different material than the main shaft body. For example, the coupling flange can be made of steel. The main shaft body is preferably flared on at least one end, and the at least one coupling flange includes a first generally frustoconical projection extending into the flared end of the main shaft body.

The normal stiffness of fiber-based shafts is achieved by the orientation of parallel fibers along the length of the shaft. However, the bending stiffness of this shaft is reduced due to the change in fiber orientation. Since the fibers continue to travel in the same direction from the first end to the second end, the reinforcement that increases the torsional stiffness of the shaft is not affected. In contrast, a fiber-based shaft is also flexible because it uses ribs that are approximately 90 degrees from the centerline of the shaft.

In addition to the helical ribs, the drive shaft 100 may also contain reinforcing elements. These reinforcing elements maintain the structural integrity of the shaft. These reinforcing elements are called helical ribs. They have ribs on both the outer and inner surfaces. This is to prevent shaft breakage. These elements can also be shaped to be flexible enough to accommodate some of the forces generated by the drive. Shafts can be designed using these methods and made into worm-like drive shafts.

vibration

The most common cause of drive shaft vibration is improper installation. There are five common types of driveshaft vibration, each related to installation parameters. To prevent this from happening, you should understand what causes these vibrations and how to fix them. The most common types of vibration are listed below. This article describes some common drive shaft vibration solutions. It may also be beneficial to consider the advice of a professional vibration technician for drive shaft vibration control.

If you’re not sure if the problem is the driveshaft or the engine, try turning on the stereo. Thicker carpet kits can also mask vibrations. Nonetheless, you should contact an expert as soon as possible. If vibration persists after vibration-related repairs, the driveshaft needs to be replaced. If the driveshaft is still under warranty, you can repair it yourself.

CV joints are the most common cause of third-order driveshaft vibration. If they are binding or fail, they need to be replaced. Alternatively, your CV joints may just be misaligned. If it is loose, you can check the CV connector. Another common cause of drive shaft vibration is improper assembly. Improper alignment of the yokes on both ends of the shaft can cause them to vibrate.

Incorrect trim height can also cause driveshaft vibration. Correct trim height is necessary to prevent drive shaft wobble. Whether your vehicle is new or old, you can perform some basic fixes to minimize problems. One of these solutions involves balancing the drive shaft. First, use the hose clamps to attach the weights to it. Next, attach an ounce of weight to it and spin it. By doing this, you minimize the frequency of vibration.

cost

The global driveshaft market is expected to exceed (xxx) million USD by 2028, growing at a compound annual growth rate (CAGR) of XX%. Its soaring growth can be attributed to several factors, including increasing urbanization and R&D investments by leading market players. The report also includes an in-depth analysis of key market trends and their impact on the industry. Additionally, the report provides a comprehensive regional analysis of the Driveshaft Market.

The cost of replacing the drive shaft depends on the type of repair required and the cause of the failure. Typical repair costs range from $300 to $750. Rear-wheel drive cars usually cost more. But front-wheel drive vehicles cost less than four-wheel drive vehicles. You may also choose to try repairing the driveshaft yourself. However, it is important to do your research and make sure you have the necessary tools and equipment to perform the job properly.

The report also covers the competitive landscape of the Drive Shafts market. It includes graphical representations, detailed statistics, management policies, and governance components. Additionally, it includes a detailed cost analysis. Additionally, the report presents views on the COVID-19 market and future trends. The report also provides valuable information to help you decide how to compete in your industry. When you buy a report like this, you are adding credibility to your work.

A quality driveshaft can improve your game by ensuring distance from the tee and improving responsiveness. The new material in the shaft construction is lighter, stronger and more responsive than ever before, so it is becoming a key part of the driver. And there are a variety of options to suit any budget. The main factor to consider when buying a shaft is its quality. However, it’s important to note that quality doesn’t come cheap and you should always choose an axle based on what your budget can handle.

editor by czh 2023-01-01

in Kingston Jamaica sales price shop near me near me shop factory supplier High Quality Tractor Snow Blower for Sale manufacturer best Cost Custom Cheap wholesaler

We will supply very best companies and substantial high quality items with all sincerity. EPG is a specialist maker and exporter that is concerned with the design and style, growth and generation. The solution nicely displays environmental protection and vitality conserving. Tractor snow blower with CE

one period of time Tractor give EPTT

three interval PTO shaft EPTn

2 period of time EPTT can be to order

three interval EPT colon Metal

4 comma Frontal snowblower and rear snowblower

five comma Fitting tractor from 20HP-55HP

The snow blower mounts on the tractor aposs rear three points hitch comma also can hook up to the front of tractors lparquick release arms layout rpar

| Product | B5418F | B5418PTO | B6618F | B6618PTO |

| Slicing WIDTH | fifty four EPT | 54 EPT | 66 EPT | 66 EPT |

| Cutting HEIGEPTT | 22 EPT | 22 EPT | 22 EPT | 22 EPT |

| Supporter | four-BLADES | four-BLADES | four-BLADES | 4-BLADES |

| Fan DIAMETER | eighteen EPT | 18 EPT | eighteen EPT | 18 EPT |

| Fan DEPTTH | four period8 EPT | four period8 EPT | 4 period8 EPT | 4 period8 EPT |

| AUGER DIAMETER | 15 EPT | fifteen EPT | 15 EPT | fifteen EPT |

| Push Enthusiast | HYD W solGEAR BOX | PTO Gear BOX | HYD W solGEAR BOX | PTO Gear BOX |

| Push AUGER | EPTT W solEPTT | EPTT W solEPTT | EPTT W solEPTT | EPTT W solEPTT |

| HITCH Variety | Front Finish LOAEPTT | three-Details CAT period I | Entrance Finish LOAEPTT | three-Details CAT period Ior II |

| HITCH ADJUSTMENT | LD PIN | LD PIN | ||

| CHUTE DEFLECTOR | HXiHu (West EPT) Dis.HU (WEST LAKE) DIS. sol4POSITION sol115 deg -a hundred forty five deg | HXiHu (West EPT) Dis.HU (WEST LAKE) DIS. sol4POSITION sol115 deg -one hundred forty five deg | HXiHu (West EPT) Dis.HU (WEST LAKE) DIS. sol4POSITION sol115 deg -a hundred forty five deg | HXiHu (West EPT) Dis.HU (WEST LAKE) DIS. sol4POSITION sol115 deg -one hundred forty five deg |

| Slicing EDGE | three sol8 EPT x4 EPT EPTTled | three sol8 EPT x4 EPT EPTTled | 3 sol8 EPT x4 EPT EPTTled | 3 sol8 EPT x4 EPT EPTTled |

| SKID Shoes | Cup variety adjustable | Cup type adjustable | Cup kind adjustable | Cup variety adjustable |

| System | hyd period of time loader stream | pto w solshear | hyd interval loader flow | pto w solshear |

| CONTROLS amp Travel | SENSING BLOCK | PIN | SENSING BLOCK | PIN |

| HYD period of time REQUIEMENTS | six period6-thirteen period2gpm 2000psi min | no | six period6-13 period7gpm 2000psi min | no |

| TRACTOR HP | 25-35hp | 20-35hp | 25-55hp | twenty five-55hp |

| APPROX WEIGEPTT | 700lbs | 700lbs | 800lbs | 800lbs |

Best sales made in China – replacement parts – PTO shaft manufacturer & factory High freelander 2 propshaft Quality Agricultural Equipment Dq854 85HP 4WD China Four Wheel Farming Tractor with Canopy with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing facility in China with 5 various branches. For a lot more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

pto bolts Our pto generate shaft for bush hog organization alter pto shaft duration is generate shaft connects to positioned discovery 2 propshaft in 1999 chevy silverado 1500 push shaft XiHu ford figo push shaft value HangZhou pto push shaft basic safety go over Zhejiang bush hog pto shaft components Province. pto shaft finish T The firm covering 88,000 sq. meters, has innovative products and powerful technological strength, this sort of as the numerical manage equipment resources and machining centers, CAD/CAM system, industrial robotic and so forth. Large top quality Agricultural equipment DQ854 85HP Four wheel drive China 4 wheel Farming tractor with Cover

Tractor Principal Features and Benefits:

1.Outfitted famous brand name motor displaying innovative ability,lower fuel intake,high economic performance.

2. Streamlined look design, stunning and generous.

3.Transmission Case undertake meshed shift and add the gearbox interlock unit helps make the procedure far more easily,dependable and easier.

four. Double action clutch with disc spring, execute steadily and effortless to operate.

five. Entirely hydraulic steering method greatly lowered driver’s perform strength.

6. Soaked disc brake device, dependable brake performance.

7. Individual injection of hydraulic oil, dependable to operate.

8. The lifter with force and place adjustment, with reliable raise.

nine. Tractor PTO:

PTO in Double speed : 540/760r/min Optional, For high doing work performance.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural tools of all more than the planet.

10. Massive Chassis and Heavy-obligation Rear axle for Durable Robust device.

11. Entire collection light-weight, ROPS,Sunshade/Canopy, Fan/Heater/Air-conditioned cabin are all accessible, for much more cozy driving setting.

Tractor Major specificaiton and Complex parameters:

| Tractor Model | DQ854 | ||

| Drive type | 4WD | ||

| Motor | |||

| Engine model | EPT or Yuchai model, 4 cylinder EPT motor | ||

| Capacity of fuel tank(L) | 150 | ||

| Engine power(kw/hp) | 62.5kw/85HP | ||

| PTO power at rated speed (kw) | 53 | ||

| Transmission | |||

| Clutch | Dry,twin-stage type | ||

| PTO Speed(rpm) | 540/1000 or 760/one thousand | ||

| Gearshift | 8F+4R(widespread) /16F+8R(optional)/8F+8R(optional) | ||

| Hydraulic system | |||

| Hydraulic output valve | 2-Group (optional) | ||

| Three point linkage | |||

| Category of 3-point link | Category II | ||

| Lifting force (at point of 610mm)KN | >16 | ||

| Technical parameter | |||

| Dimension LxWxH (mm) | 4593x2050x2810 | ||

| Wheel base(mm) | 2195 | ||

| Track base(mm) front wheel | 1610 | ||

| Track base(mm) rear wheel | 1620-2571(usual 1620) | ||

| The smallest clearance(mm) | 379 | ||

| Front tyre | 11.2-24 | ||

| Rear tyre | 16.9-34(widespread) / 18.4-thirty(optional) | ||

| Optional Configurations | |||

| Common cabin with Fan Heater cabin AC cabin ROPS Canopy (Sunshade) 8F+8R shuttle gearshift, 16F+4R creeper gearshift, 2-Group Hydraulic output valve Front ballastRear ballast Paddy tire, 18.4-thirty big rear tire, Air brake, Swing draw bar | |||

| Loading Quantity/40HC | 3 Sets in Nude packing for CBU transport | ||

DQ854 85HP 4 wheel drive Tractor detai EPT :

Top-rank technical staff and EPT R&D Middle :

EPT Creation workshop :

Strictly examine for each established device before Items Supply :

Firm Honors and Certificates:

Customized Packing and Transporting Support to meet different customers’ demand :

EPT soon after-sale provider for the two Distributors and Private customers:

Please speak to us if you have any need for our Product :

Greatest price tag will be quoted for you as quickly as receive your Necessity !

Best Cost made in China – replacement parts – PTO shaft manufacturer & factory Peru chelsea pto kit Hot Sale High Quality Dq1504 150HP 4WD Four Wheel Agricultural Farm Tractor with ce certificate top quality low price

We – EPG Team the greatest agricultural gearbox and pto manufacturing unit in China with 5 various branches. For more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

toyota rav4 drive shaft pto shaft for bush hog tractor supply EPG discovery 2 entrance propshaft is pto adapter plate specialized ebay pto shaft in weasler pto drive shaft design and style, pto shaft adaptor producer 2011 jeep grand cherokee rear travel shaft and huge one thousand to 540 pto adapter sales tsc pto shaft of agricultural equipment and farm implements, which has an unbiased import and export legal rights. EPG Machinery is located in XiHu Spot HangZhou Zhejiang ,China. It is 30km from our manufacturing facility to HangZhou international airport. Peru hot sale Higher high quality DQ1504 150HP 4 wheel drive 4 wheel Agricultural Farm Tractor

Tractor Primary Characteristics and Benefits:

one.Equipped popular model engine demonstrating advanced ability,minimal gas use,higher financial performance.

two. Streamlined physical appearance style, stunning and generous.

three.Transmission Circumstance adopt meshed shift and include the gearbox interlock system helps make the procedure more smoothly,reliable and easier.

4. Double motion clutch with disc spring, perform steadily and effortless to function.

5. Completely hydraulic steering program greatly reduced driver’s work energy.

six. Damp disc brake system, reliable brake efficiency.

7. Different injection of hydraulic oil, reliable to operate.

eight. The lifter with power and situation adjustment, with trustworthy elevate.

nine. Tractor PTO:

PTO in Double pace : 540/760r/min Optional, For high doing work effectiveness.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural tools of all more than the world.

ten. Large Chassis and Large-obligation Rear axle for Durable Sturdy equipment.

eleven. Entire collection light, ROPS,Sunshade/Canopy, Enthusiast/Heater/Air-conditioned cabin are all available, for far more comfy driving atmosphere.

Tractor Principal specificaiton and Specialized parameters:

| Product | DQ1504 |

| Drive sort | 4×4, 4wd wheel type |

| Motor | |

| Engine manufacturer and product | EPT model, EPT motor Product LR6M3Z-23 |

| Sort | In-line, immediate injection,Drinking water cooling, 4 stroke,6-cylinder |

| Aspiration way | Turbo |

| Motor energy at rated pace | a hundred and ten.3kw/150HP |

| Rated Electricity of PTO | ninety four KW |

| Max. traction Force (KN) | 32.five |

| Displacement(L) | 7.thirteen |

| Compression ratio | 18:one |

| Rated speed (r/min) | 2300 |

| Least expensive gasoline use (g/kw.h) | ≤210 |

| Cylinder·Bore·Stroke | six-110×125 |

| Gasoline tank capability (L) | 350 |

| Muffler Dimension (Dia.×Length) (mm) | φ600×295×140 |

| Muffler weight (kg) | 7.2 |

| Steering kind | Complete Hydraulic steering |

| Transmission | |

| Clutch | United states of america JpV brand name, 13 inch twin-phase Clutch |

| PTO Velocity (rpm) | 540/a thousand |

| Gearshift | 16F+8R |

| Velocity range (km/h) | F: 1.37-32.93 / R:2.09-30.sixty three |

| Driving brake | Moist, disk, hydro-static run |

| Gearbox | 4×2×(2+1) |

| Gearbox shifting way | Joggle cover |

| Walking system | |

| Frame type | Frameless |

| Tyre measurement( entrance/rear) | fourteen.9-26/18.4-38 |

| Force( entrance/rear) (kPa) | 157-196/one hundred fifty-two hundred |

| Rim materials | 330CL |

| Doing work device | |

| Lifter sort | Semi-detached product |

| Max. Lifting pressure (KN) | 27 |

| Suspension design | Rear, 3-position linkages |

| Suspension group | Category II or III |

| Changing manage | Position control, float handle |

| Hydraulic pump type | Equipment pump CBN-E325L |

| Hydraulic output valve | three Groups |

| P.T.O. variety | 1 kind, rear |

| Spline no. of P.T.O. | 6( stHangZhourd), 8, 21 |

| Diameter of spline | 35 |

| RPM | 540/one thousand or 760/one thousand |

| Technical parameter | |

| General Dimension (LxWxH) (mm) | 5240×2345×2995 |

| Wheel base (mm) | 2530/2657 |

| Monitor base-Front /R(mm) | 1650-2285 (1950 ex-operate) /1620-2420 (1850 ex-operate) |

| Observe foundation adjusting way | Restricted/unlimited |

| Minimal floor clearance (mm) | 520 |

| Min. operational fat (kg) | 4755 |

| Front /Rear axle weight (kg) | 2050/2705 |

| Front Ballast | 440kg (eleven pcs, 40kg/pcs) |

| Rear Ballast | 520kg (2 lays each and every facet) |

| Masking | Air-conditioning Cabin or Sunshade (Canopy) |

| Structure excess weight (kg) | 5400(without having cabin)/5780 (with cabin) |

EPT Manufacutring Line:

Strictly Inspecting and Total Screening for making certain substantial good quality product:

Tractor Packing and Loading container for Providing items :

Numerous Transportation modes and Shipping phrase to fulfill various buyers demand :

Best price will be quoted for you as quickly as receive your Necessity !

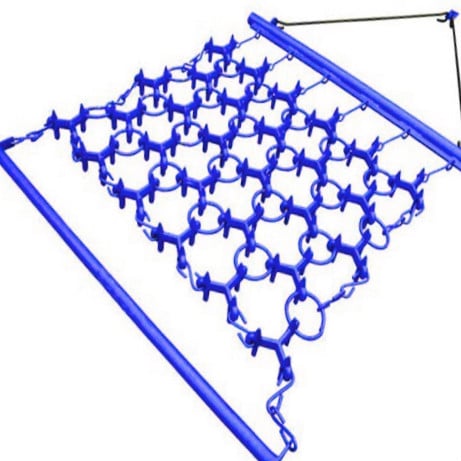

Best China manufacturer & factory china in Kolhapur India manufacturer Hot selling high quality tractor disc plough is suitable for agricultural machinery With high quality best price

It has established stable cooperation with several well recognized universities and institutes in china this sort of as, Zhejiang College, Jilin University, Technological committee of countrywide chain travel common, Institute of countrywide chain travel, Zhejiang application engineering content institute, Huhan material protection institute and it cooperated to identified China Very first Automobile chain institute with National chain generate institute.

Overview

Fast Information

- Guarantee:

-

one.5 a long time

- Relevant Industries:

-

Farms

- After Guarantee Support:

-

Movie specialized assist

- Regional Service Location:

-

Canada, Turkey

- Showroom Location:

-

Egypt

- Video clip outgoing-inspection:

-

Offered

- Machinery Check Report:

-

Presented

- Marketing Type:

-

New Merchandise 2020

- Guarantee of core factors:

-

one.5 a long time

- Core Elements:

-

Gearbox, Equipment

- Key Selling Factors:

-

Long Services Life

- Substance:

-

65Mn or Boron metal

- Colour:

-

Black Yellow Blue

- Title:

-

Tractor Disc Plough for Farm Device

- Search term:

-

20kg

- Hardness:

-

HRC38~forty four

- Diameter:

-

510 or 560mm

- Gap Dimension:

-

Squared 31*31mm or optional

- Thickness:

-

3~12mm

Packaging Near up of two yokes with the common joint. Observe the slight oozing of grease from the UJ seal ends, the clump of grease is from inside the yoke splined shaft location –Drive (outer) yoke has a woman (typical spline) gap and “Y” shape finish that is the common joint (UJ) mount. –UJ is a cross formed casting possessing roller bearings enclosed with caps at all 4 points and is held into the yoke with four “C” clips –Inner yoke and generate shaft is one more yoke welded to the travel finish, of the drive shaft. –Driven shaft and internal yoke is the driven shaft that rides inside of the push shaft and has a yoke welded at the driven finish –UJ yet another UJ as previously mentioned& Shipping and delivery

-

Direct Time

: -

Quantity(Luggage) one – 500 501 – one thousand >1000 Est. Time(days) 38 45 To be negotiated

On-line Customization

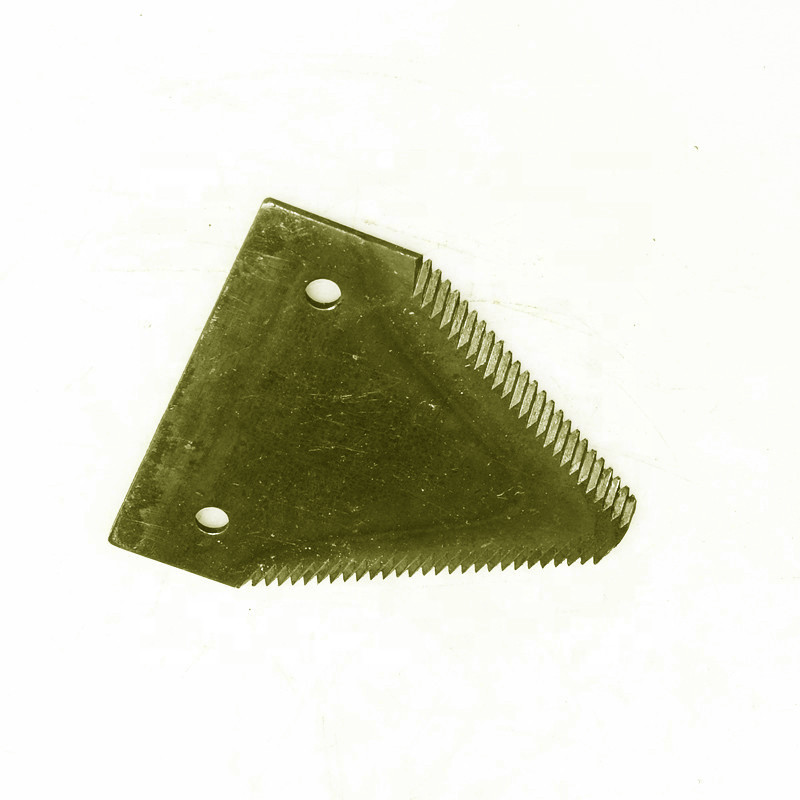

Product Description

|

Solution Identify |

Agricultural equipment parts |

|

Content |

65mn,60si2mn,38MnB5 |

|

Color |

crimson,black,blue or as your need |

|

Normal |

IS9001 |

|

Attribute |

Long making use of life and the affordable cost |

|

Surface Treatment |

Spray Paint,Energy Painting,Galvanized |

|

Advantages |

Professional production staff,excellent engineer,high good quality productions |

|

Utilized |

Farm Device |

Goods Display

Our Business

Manufacturing unit

Our Manufacturing unit

Workshop

Our Workshop

Warehouse

Our Warehouse

Staff

Our Group

Packing & Supply

Packing Information : Wooden cases or Tito

Shipping Details : 45 days soon after order

one. Particular logistics packaging

two. Suitable carton dimension

3. Shock bubble film

four. Skilled placement

five. Professional shock

six. Comprehensive bundle

Our Certifications

Client Image

ABOUT US

OurHIGH-Finish OR Standard – OUR Customers HAVE THE Option Consumers can gain from our strengths in two quite various locations of our portfolio: on the a single hand, we provide a wide selection of products in the reduced-to-mid efficiency variety. On the other, we build an array of answers for even the most tough generate apps. manufacturing unit is specializing in the generation of agricultural machinery and forestry equipment chopping tool items, supplies this sort of as 65MN, 60SI2MN, 30MNB5,45#, and numerous other sorts of resources. Merchandise: harvester blade, tiller blade, blade mower, deep plowing machine components and so on

A skilled rotarycolter manufacturing unit

EPG – a single of the greatest Agri-Machinery parts manufacturing facility in China Co., Ltd., our factory has 19 years of background. The company has 200 workers, including 18 skilled and technical developers and twenty screening staff.It specializes in producing more than 5000 agricultural equipment items and offering them to 85 nations around the world

FAQ

Q: Are you investing organization or producer ?

A: We are manufacturing facility.

Q: How extended is your delivery time?

A: Normally it is 5-ten times if the goods are in inventory. or it is fifteen-twenty times if the items are not in inventory, it is in accordance to quantity.

Our organization has reliable financial strength, builds up a technician group contingent with higher top quality, possesses the manufacturing assembly line of technicalization in China and perfect program examining on solution quality and runs marketing networks during the region. Q: Do you give samples ? is it free of charge or additional ?

A: Of course, we could supply the sample for totally free demand but do not shell out the expense of freight.

Q: What is your conditions of payment ?

A: Payment=1000USD, 30% T/T in progress ,balance before shippment.

If you have an additional question, pls come to feel free to speak to us as underneath:

Contact

Alan

E-mail :hzpt @hzpt.com

WeChat.:hzptusa

Best China manufacturer & factory Hot in West Rand South Africa Sale Agricultural Gearbox 90 degree farm pto right angle tractor slasher rotary tiller pga feeder mixer earth auger noncomer With high quality best price

We examine every piece of bearing by ourselves prior to supply.

Overview

Rapid Particulars

- Relevant Industries:

-

Production Plant, Machinery Restore Outlets, farms

- Brand Title:

-

OEM

- Gearing Arrangement:

-

SPUR

- Output Torque:

-

20Nm

- Enter Pace:

-

540rpm

- Output Velocity:

-

Ratio1:1.47,1:1.92

- Model Number:

-

XH30.147Z.01L/03L,XH30.192Z.03L

- Rated Energy:

-

EPG main creation is of farming fifteen-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and equipment.

30HP

- paint:

-

pink or black primary coat

- fat:

-

Accudrive Servo Gearheads Servo drives from EPG Push gain from the knowledge and innovation of our a lot more traditional brands. Accessible in each right angle and inline configurations, coupled with the availability of a number of precision ranges, you are certain to find the proper merchandise for your software.EPG Drive Accudrive Servo Gearhead

16.85kg

Provide Capacity

- Provide Ability:

- 20000 Piece/Parts per Yr or more

Packaging & Shipping

- Packaging Specifics

- wood situation suitable for exportation

dimension:1120*1050*740mm

- Port

- Shanghai and many others.

-

Direct Time

: -

Amount(Pieces) 1 – 2000 >2000 Est. Time(times) forty five To be negotiated

Online Customization

Very hot Sale Agricultural Gearbox

This series gear box is largely utilized on mower (grass cutter). It has the traits of high univerality, straightforward framework and excellent overall performance.

Specifics:

– ISO9001 Good quality Method examined & confirmed by Third Celebration of CQC and handed next-diploma protection high quality standardization for equipment manufacturing business.

– Precision forging, chopping by CNC equipment, warmth treatment method by German IPSON & laser tactics .

– Strictly quality control by German CMM.

– Different of gearboxes utilised in agricultural machines and industrial equipment.

– Sophisticated teThe lemon tube is appropriate for transmissible power of sixteen-35HP, it is the favored selection for large speeds and lower torque transmission. The two-lobe lemon tube grants low vibrations up to 2600 rpm with lengths not exceeding 800mm. AC collection with six-lobe tubes (star)chnics, powerful self-advancement electricity, in a position to create new sort gearbox in accordance to customer’s design and style drwings.

| Code |

Input Energy (HP) |

Equipment Ratio (i) |

Enter Pace (r.p.m.) |

Bodyweight (kg) |

| XH30.147Z.03L | 30HP | one:1.forty seven | 540 | sixteen.eighty five |

| XH30.192Z.03L | 30HP | one:1.92 | 540 | 16.85 |

Quality Assurance:

Style Patent:

Company Tradition: